When introducing customers to your product, first impressions will be made with your label. To make an unforgettable first impression and ensure that your labels are attractive and eye-catching, it is important to select a method of printing that will meet the high level of expectation and competition in the market. The method you choose should minimize your cost and time, but the end results should be high quality.

When introducing customers to your product, first impressions will be made with your label. To make an unforgettable first impression and ensure that your labels are attractive and eye-catching, it is important to select a method of printing that will meet the high level of expectation and competition in the market. The method you choose should minimize your cost and time, but the end results should be high quality.

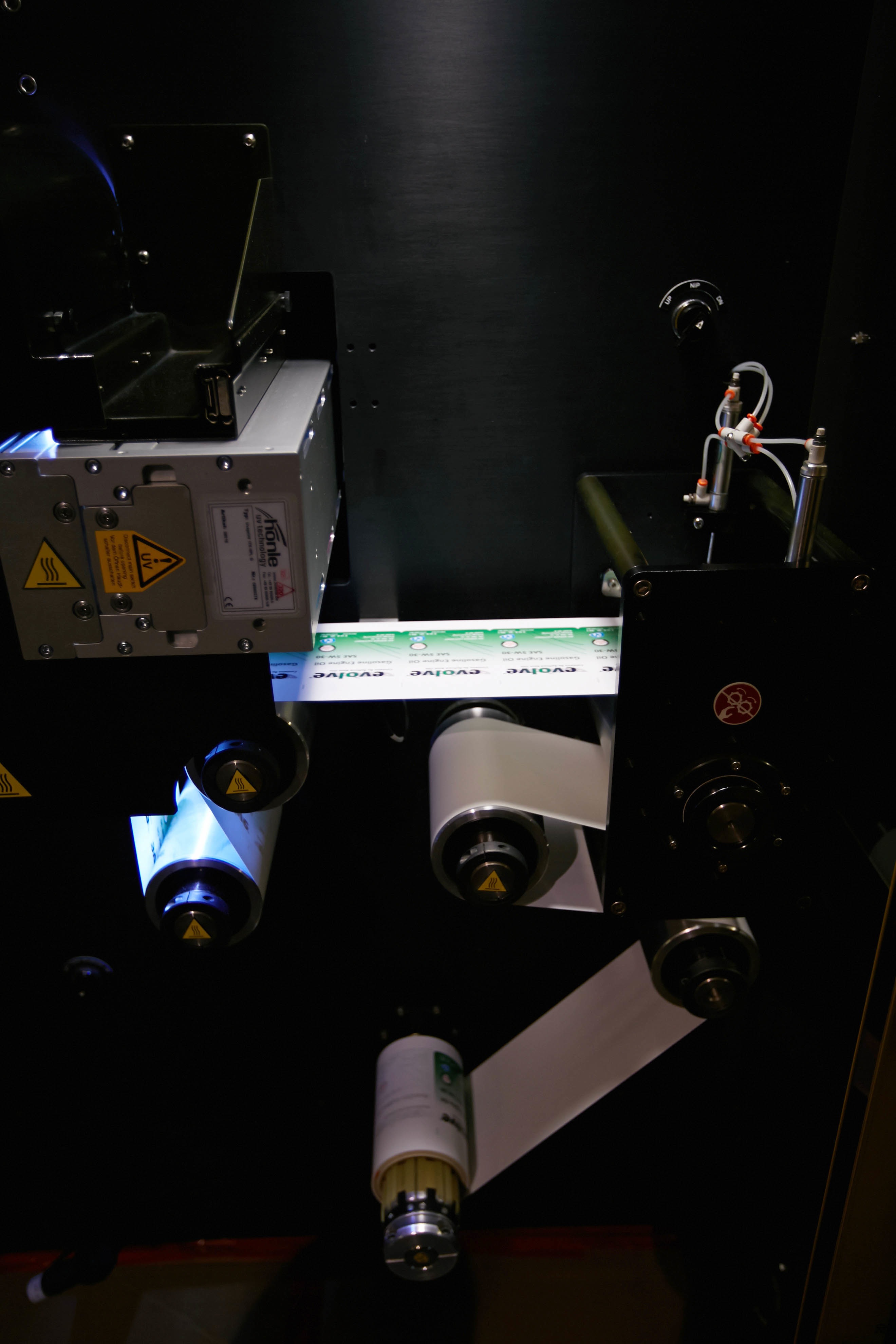

Digital printing is a method that can produce vivid, high quality labels that can be used for practically any project. If you’re wondering what the advantages digital printing are over other methods of printing, here are five advantages of choosing digital printing for your product labels:

- High Quality. Vibrant product labels grab the attention of the consumer. Certain types of digital presses can produce resolutions of nearly double what a traditional flexographic press can and delivers a label with crisp, clear images and life-like colors.

- Turnaround Time. Since no plates are required in this method of printing, you will not have to pay for a printing plate for each color on the label. No plates also means shorter set-up time, so your labels can be printed faster.

- Cost. Because you are not paying for plates and additional set-up time, the cost for digital printing of labels is much less for short run labels as compared to the flexographic method of printing.

- Short Run Capability. For small quantities of custom labels or “short run labels,” the benefit of printing digitally is maximized because you can order only the amount of labels you will need immediately, rather than ordering labels in bulk in order to get the best price.

- Design Flexibility. If you decide that your label needs adjustments to better attract your target audience, the cost or reprinting it can hurt your bottom line. New plates will need to be configured and set-up charges will again apply. If you have multiple product label designs, costs can add up even quicker. With digital printing, there are no plate or set-up fees, so your labels can be printed right away.

If you need help deciding which label printing method is most beneficial for your business, contact us and we will make some suggestions based on your product. If you would like additional information on how to take advantage of the digital printing methods for your label, click here and we will get back with you with some tips for transforming your label digitally.