You may not realize it, but a lot of work goes into printing a label and making it the identifying feature on food, beverage, or other packaging. Here’s a brief overview on how Louisville Label gets the printing job done.

When it comes to printing a label, Louisville Label has two basic types of printing processes: Digital Printing and Flexo Printing.

Digital Printing

Digital Printing is a process in which the label template is taken from the computer to the digital press, no printing plates are needed or required. When a customer requires small runs or is looking for very high quality but doesn’t want to invest in all of the prep costs associated with printing, digital printing is the way to go. Because there are no prep costs in digital printing, this route can often be less expensive and can also bring shorter lead times.

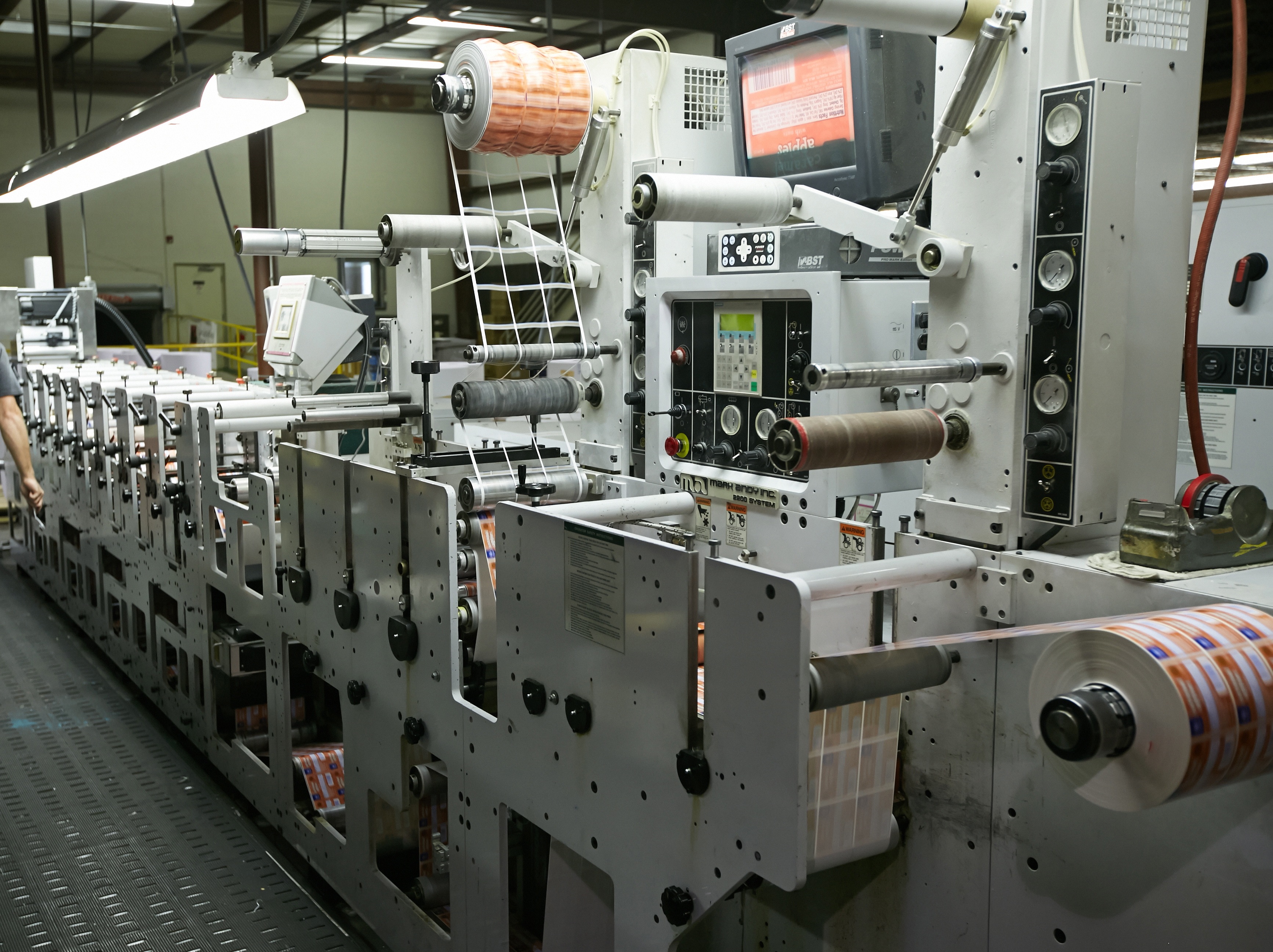

Flexo Printing

Flexo Printing, or Flexography, is a form of printing which utilizes a flexible relief plate, which is similar to a modern version of letterpress. Most any type of substrate, including plastic, metallic films, cellophane, and paper can be used for printing. This type of printing is also widely used for printing on non-porous substrates that are required for various types of food packaging. Flexo printing is a good fit for any job requiring large areas of solid color to be printed. Jobs which involve longer runs and expect very high quality are good candidates for flexo printing, where the customer also has more control over the end product.

Flexo Printing, or Flexography, is a form of printing which utilizes a flexible relief plate, which is similar to a modern version of letterpress. Most any type of substrate, including plastic, metallic films, cellophane, and paper can be used for printing. This type of printing is also widely used for printing on non-porous substrates that are required for various types of food packaging. Flexo printing is a good fit for any job requiring large areas of solid color to be printed. Jobs which involve longer runs and expect very high quality are good candidates for flexo printing, where the customer also has more control over the end product.

Whatever the style, Louisville Label offers your business a label that proudly displays all of your pertinent information, yet appeals visually to consumers and customers around the globe.